"Take the best that exists and make it better. When it does not exist,

design it."

Sir Henry Royce

Reliability Engineering Services

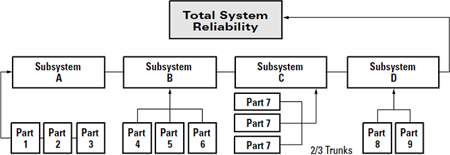

System Reliability

Located near Phoenix, Arizona, Proof Engineering provides reliability analysis and reporting to companies that supply mechanical and electromechanical products to the US government. We analyze your system part by part, evaluating the likelihood of failure of each component through mathematical calculations and/or FEA and then combine the results to an overall system reliability in terms of a mean time between failure (MTBF). In cases of poor reliability, we help you to problem solve and generate solutions to improve the reliability of your product.

In addition to satisfying requirements of DoD directive-type memorandum 11-003 (reliability analysis, planning, tracking, and reporting), knowing the reliability of your system is a useful internal tool for comparing designs, estimating warranty costs, and defining objectives for physical tests.

Parts Count Method

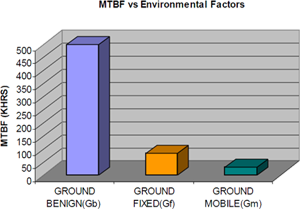

The parts count method is the simplest approach to obtaining overall system reliability. Either physics-based models or databases of failure rates may be used for each unique component. Because exhaustive test results are not always available, results of this type of analysis are often conservative. For instance, databases of failure rates such as NPRD 2011 assume one failure rate even though none may be observed due to time constraints.

Parts Stress Method

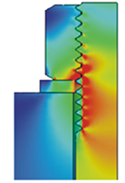

The parts stress method is a more exhaustive and accurate approach to reliability prediction and in many cases, less costly than performing physical tests. In this type of analysis, component stresses may be calculated by hand or through use of the finite element method. This method seeks to predict stresses created by loads seen in the field, in the system's actual operating environment. Stresses collected from FEA are then compared to material fatigue models and a failure rate is then determined.

Applications

Just a few examples of potential applications:

- Military vehicles and aircraft

- Commercial helicopters and airliners

- Satellites

- Automated motor vehicles

- Unmanned aerial vehicles (UAVs)

- Launch vehicles

- Autonomous vehicles

- Navy vessels and equipment

- Military equipment and weaponry

- Hydraulic fracturing

- Nuclear plants

- Offshore drilling

Reliability Services:

- Mean time between failures (MTBF)

- Customized, written reports)

- Mean distance between failures (MDBF)

- Finite element analysis (FEA - stress analysis )

- Thermal stress analysis

- Fatigue analysis

- Fracture mechanics

- NASGRO analysis

- AFGROW analysis

- Failure modes and effects analysis (FMEA)

- Failure modes, effects and criticality analysis (FMECA)

- Fault tree analysis

- Failure modes and effects analysis (FMEA)

- Design for Six Sigma

- Design of Experiments (DOE)

- Root cause analysis

- Reliability test planning

- Static and dynamic testing

White Papers:

Written by our experts:

Misc. Resources:

An Overview of Reliability Analysis: